More stories

-

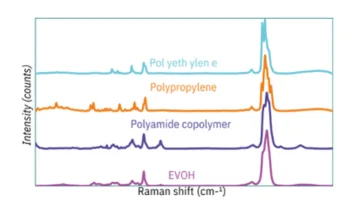

Innovative Raman Technology Unlocks the Future of Sustainable Packaging

Cybersecurity in the Modern Business Era: A Closer Look at Online Verification and Its Impact In today’s digital landscape, the idea of online security has become as essential as the gears in an engine. With every click and every transaction, businesses – whether small or industrial manufacturing behemoths – must deal with a variety of […] More

-

EOS Unveils Extended Metal Powder Family With Four New Alloys

Innovations in Metal 3D Printing: EOS’s Strategic Expansion of Alloy Offerings The world of metal additive manufacturing has been evolving at a rapid clip, and one of the most exciting developments today comes from EOS GmbH. In its latest move, the company has added four new metal powders to its portfolio – an initiative that […] More

-

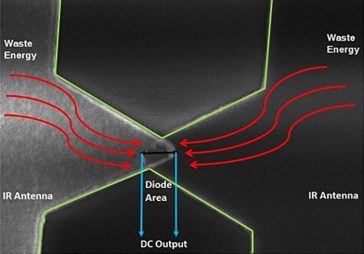

Quantum Innovations Fuel a New Era in Energy Harvesting

Breaking Boundaries: Quantum Energy Harvesting and Its Potential The recent breakthrough in energy harvesting marks a pivotal turning point in the world of sustainable technology. Researchers from Japan have introduced an innovative approach that pushes beyond the traditional limits defined by thermodynamics, offering a fresh perspective on converting waste heat into useful electricity. In this […] More

-

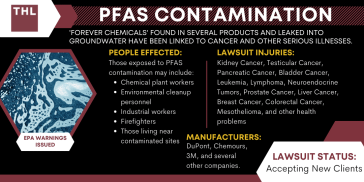

Temporary Triumph in the Endless Battle Against Forever Chemicals

Environmental Accountability and the Battle Over PFAS Drinking Water Standards The debate over PFAS – the so-called “forever chemicals” – has evolved into one of the most pressing issues for communities and regulators alike. Over the last several years, local activists in North Carolina and across the nation have wrestled with tangled issues surrounding drinking […] More

-

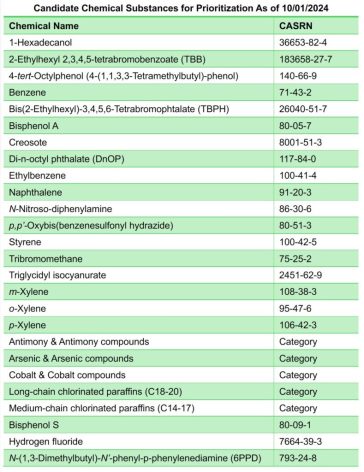

Senators Demand Swift TSCA Reforms as EPA Nominee Faces Tough Congressional Scrutiny

Senate Confirmation Battles: Balancing Industry Experience and Public Health Priorities The debate over the nomination of Douglas Troutman for the position of EPA assistant administrator for toxic substances has brought to light the conflicting priorities inherent in today’s chemical regulation landscape. At the heart of the matter lies the tension between speeding up the review […] More

-

Houston Innovation Awards Spotlight Minority Entrepreneurs Leading Business Innovation in 2025

Houston’s Dynamic Innovation Landscape: A Celebration of Minority-Founded Startups Houston has long been known for its diverse population and entrepreneurial spirit. In recent years, the city has evolved into a bustling hub for startups where creativity meets determination. The Houston Innovation Awards, an event that honors the most groundbreaking ideas in the region, has embraced […] More

-

BIS Expands Entity List to Tighten Exports to Iran

Evaluating the BIS’ New Entity List Additions: Implications for Global Trade The recent decision by the Bureau of Industry and Security (BIS) to add 29 entities to its Entity List has sparked heated conversation among industry leaders, small business owners, and trade professionals. This new ruling, affecting companies with alleged ties to Iran’s procurement networks […] More

-

Milberg Krause and Kinsman Challenge Harcros Chemicals with Dual Class Lawsuits

Overview of the Toxic Emissions Lawsuit in Kansas City In recent weeks, a pair of class action lawsuits have emerged that underscore issues of accountability and public health in Kansas City, Kansas. These legal actions, brought forward by plaintiffs with representation from renowned environmental litigators, claim that Harcros Chemicals Inc. and its associated legacy companies […] More

-

Trending

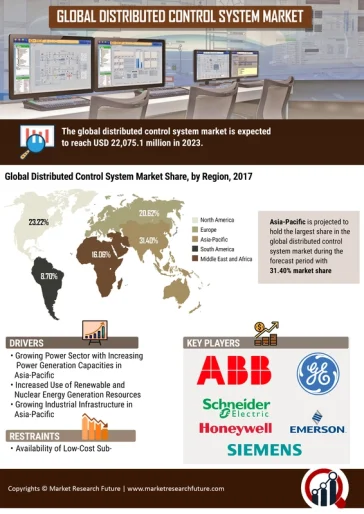

Distributed Control Systems Market Poised for Robust Growth and Innovation

Distributed Control System Market: A Transformative Force in Industrial Automation The distributed control system (DCS) market is reshaping industrial processes worldwide. As industries increasingly seek to optimize efficiency, improve safety, and enhance productivity, DCS solutions are stepping in as a must-have technology for modern plants. This opinion editorial takes a closer look at how these […] More

-

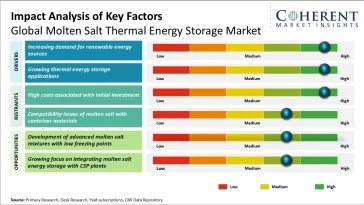

Molten Salt Falls Short of Industrial Heat Storage Promise

Enhancing Online Security and User Trust In today’s digital world, the process of verifying that a user is indeed human is a small but essential checkpoint that almost every website must implement. When you land on a site like CleanTechnica, you may be greeted by messages such as “Verifying you are human. This may take […] More

-

MnDOT Takes Decisive Action With Safety Stand Down After Back To Back Construction Fatalities

Shifting Tides in the World of Small Business and Industrial Manufacturing The landscape of small business and industrial manufacturing is undergoing dramatic changes that few could have predicted even a few years ago. In today’s rapidly evolving economic environment, owners and managers face a host of challenges and opportunities. From the tricky parts of staying […] More

-

New Yorkers Stand United Against Expanding Ebattery Storage Giants

Battery Energy Storage Systems: Boon or Risk? In recent years, our growing appetite for renewable and clean energy has led power companies and governments to invest heavily in Battery Energy Storage Systems (BESS). These systems, which store energy in thousands of lithium-ion batteries loaded into metal containers, are seen as a critical component for sustaining […] More

-

Oliver Vynerib Earns a Prestigious Green Building Award in Westport CT

Championing Sustainable Deconstruction in Westport: A New Chapter for Green Building In recent times, the idea of sustainable construction and demolition has evolved into a powerful movement that not only benefits our environment but also fosters community development. Westport, CT has quickly become a leader in this movement, thanks to the dedicated efforts of local […] More

-

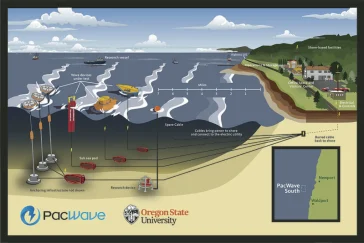

BPA Pioneers Wave Energy Innovation at Oregon State University

Wave Energy: A Bold Step into a Renewable Future on the Oregon Coast The Oregon coast has long been synonymous with breathtaking landscapes and a rich maritime legacy, but today it is also emerging as a beacon of renewable energy innovation. Oregon State University’s groundbreaking PacWave testing facility promises to transform the region’s approach to […] More

-

Brazil Sparks a Moderate Revival in Plastic Recycling for 2024

Securing the Digital Frontier: Embracing Trust in an Uncertain Online World The world of business has evolved at such a rapid pace that even the smallest digital delay can cause far-reaching repercussions. In today’s hyper-connected environment, where a simple website verification—like the one performed by www.sustainableplastics.com—echoes a broader digital security paradigm, companies of all sizes […] More

-

LyondellBasell Celebrates Supply Chain Brilliance with Nissan Monozukuri Spirit Award

Supply Chain Resilience in a Changing Global Landscape The recent recognition of LyondellBasell by Nissan with the prestigious Monozukuri Spirit Award for supply chain excellence is more than just an accolade—it symbolizes the essential strength that modern supply chains must have to succeed in this era of shifting market demands, tangled issues, and unpredictable global […] More